- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

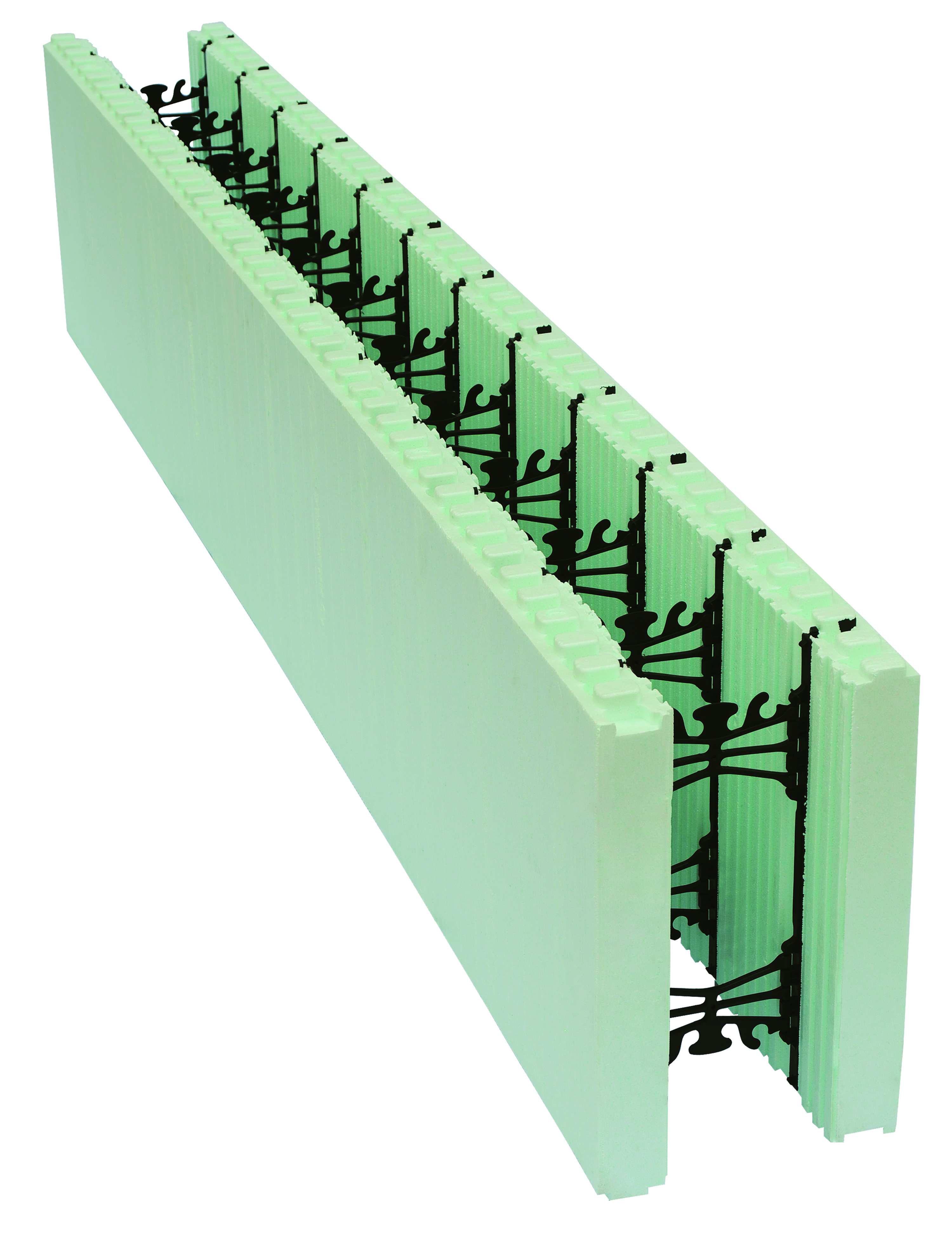

Our Insulated Concrete Forms (ICF) provide you the freedom and versatility to design and build a structure the way it was envisioned. The result is a more energy-efficient, sustainable and comfortable home or structure than those built with more traditional materials like wood or steel. Create the project of your dreams with ICFs and accessories that speed construction times and offer endless building applications.

A comprehensive wall system with products you can trust!

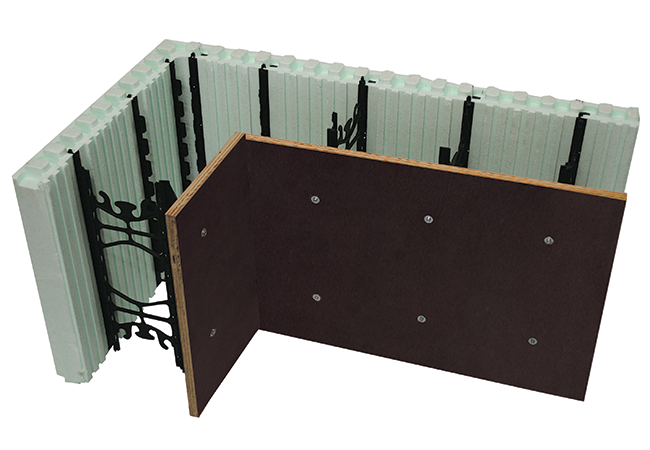

Starting your walls with Nudura ICFs and incorporating waterproofing, window and door bucks, sealants and flashings from the Tremco Construction Products Group (CPG) product line-up allows builders and design professionals to offer their customers One Wall. One Solution. That means a comprehensive ICF wall system backed by the best warranty in the industry, a complete, compatible solution you can trust.

Speed up the building process, reduce waste, and deliver architectural impact with our ICFs that offer ease of installation and ensure your project meets design requirements

Nudura ICF construction combined with Prebuck engineered window and door lumber provide the perfect wall solution. Offering the strongest, fastest and smartest construction solution, saves time and money, while building superior durability into every project.

Enjoy design versatility and offer users the ability to reduce labor with the industry's first multi-link form by not having to strip foam for elevator shafts, stairwells and other areas that do not require foam.

Pairing waterproofing and air barrier products from Tremco with Insulated Concrete Forms (ICF) from Nudura is the latest collaboration from the Tremco Construction Products Group companies.

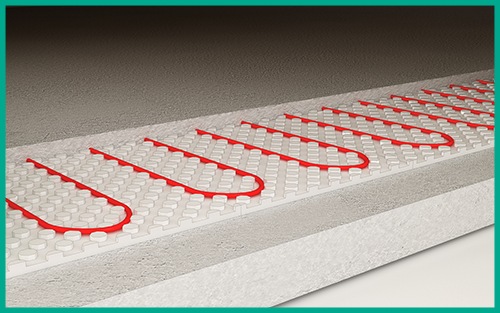

Maximize energy efficiency with insulation products that work together with our ICFs to improve your structure’s performance. Easy installation perfect for DIYer

Further reduce heating and cooling costs with our Plus+ Series of ICFs that feature more insulation than our standard forms and can achieve R-values as high as R-48

Giraffe is the highest quality ICF Alignment System on the market today. Our innovative design makes it the most trouble-free and reliable system for all your ICF projects, from residential to commercial, single-story to multi-story and regular walls to tall walls.

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.