- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

Prebuck & Nudura

Working Together

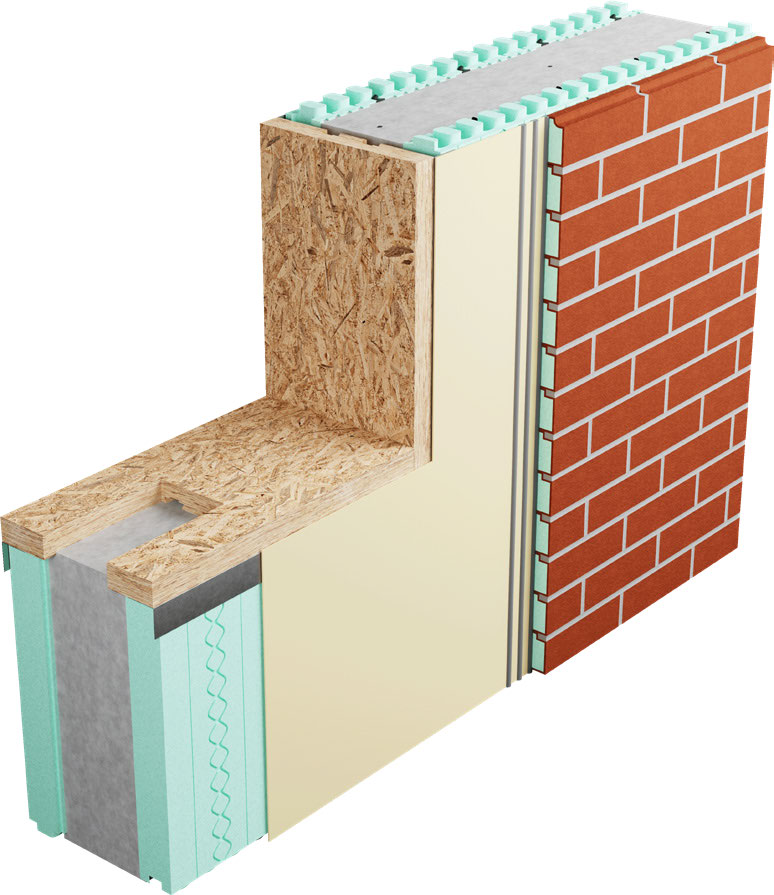

Nudura Insulated Concrete Forms combined with Prebuck engineered window and door lumber provide the perfect wall solution. Offering the strongest, fastest and smartest construction solution, ICF and Prebuck saves time and money, while building superior durability into every project.

Prebuck is specifically designed for direct contact with concrete and non-corrosive to metals, Prebuck products feature TimberStrand Strandguard (LSL) engineered lumber treated with zinc borate for exceptional resistance to insects and decay. Prebuck products also feature MDI resin, the 100% waterproof bonding agent that turns to a durable plastic when cured.

Together, Nudura ICFs and Prebuck’s engineered lumber create most efficient construction method available today.

Products

Prebuck Window and Door Buck offers the contractor, owner and design community an engineered solution for punched openings. Produced with 1-½” (38 mm) thick, treated Laminated Strand Lumber (LSL), Prebuck Window and Door Buck assures that the rough frame of the opening provides stable support for glazing and finish components. Prebuck offers many customized options that reduce labor and staging costs. Made with materials that allow direct contact with concrete, a cast in place version integrates a dual keyway design to assure a secure interface from concrete to finishes.

Features & Benefits

- Self aligns on the wall which makes for easy install—cutting days (even weeks!) off installation time

- Treated LSL product will not delaminate, become spongy or loosen fastener strength—will not cup, twist, warp or curl

- Dovetail concrete key-ways internal design allows for maximized attachment, and integrates the framing system into ICF construction eliminates air infiltration and are nonobstructive with ICF webbing

- Optional metal galvanized flange system allows for ICF bracing and building components to attach flush to the wall surface

- AWPA Standards for use category (uc2)

- Contributes to LEED Points

- NAHB National Green Building Certified

Prebuck Wet-set Sill made with materials that allow direct contact with concrete offers the contractor, owner, and design community an engineered solution for flatter, straighter sill plates. Produced with 1 ½” (38 mm) thick, treated Laminated Strand Lumber (LSL) our sill solution is produced straight and stays straight. Our sill plate solution is designed to fit ICF wall widths and using our oblong countersunk holes lets the contractor set the sill plate the same day they pour the walls.

Features & Benefits

- 16’ (4.8m) standard length

- Oblong countersunk openings

- Treated LSL product will not delaminate, become spongy or loosen fastener strength—will not cup, twist, warp or curl

- LSL bending strength minimizes need for internal bracing before concrete pour

- Designed for direct contact with concrete

- Non-corrosive to metals, insect and fungus resistive

- NAHB National Green Building Certified Nudura

- AWPA standards for use category 2 (uc2)

- Contributes to LEED points

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.