- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

By Scott Carpenter

For architects who need to design energy-efficient structures without changing their typical design processes, insulated concrete forms (ICFs) offer the ideal combination of insulating power, design and aesthetic versatility, and ease of installation.

An insulated concrete form is comprised of two layers of EPS filled with concrete and supported with rebar, and it is used for foundations and structural walls. These forms provide thick, continuously insulated walls that come with many additional benefits.

ICFs help architects, designers and contractors stay on schedule, build durable, beautiful projects and meet or exceed increasingly strict energy codes for insulation. Constructing with ICFs reduces the building’s carbon footprint and saves money on energy bills and reduced maintenance and repairs when compared to traditional building methods, such as wood frame construction. According a study from the ICFMA, ICF construction generated up to 60% energy savings and provided 58% better effective R-Value/RSI.

Plus, you can build year-round with ICFs, even in below-freezing temperatures, so you never have to slow operations. With traditional wood framing, you have to constantly clear the materials, such as the subfloor and bottom wall plate locations, of any snow or ice before you can start working for the day. There’s also a constant threat of moisture seeping into the wood, and tools such as compressor lines can freeze and batteries die faster, slowing down, if not halting, work. With ICF construction, you don’t have to clear the subfloor to work, and can concentrate on building up the walls instead. Nail guns aren’t needed, so there’s no worry about batteries or compressor tubs freezing, and the ICF forms immediately begin to insulate the project, so you have better working conditions right away.

Also ICFs are typically easier and quicker to install than traditional frame construction, which further reduces labor costs.

Explaining ICF

Sandwiching a solid concrete, rebar-reinforced wall, an ICF block’s EPS insulation can vary in thickness depending on the project’s specific needs. However, no matter the thickness or concrete core, ICF is a great way to get double-insulated mass walls in a very short period of time.

Architects and designers can use ICFs for almost all residential and commercial below- and above-grade walls, including office buildings, hospitals, schools, multi-family structures and more.

ICF continues to gain popularity with each passing year, resulting in an increased need for builders and subcontractors. To help educate more trades on working with ICF, manufacturers and trade associations offer online and in-person training so the various trades can learn how to address these. The National Ready Mixed Concrete Association (NRMCA) Build with Strength program offers many educational opportunities around designing and building with ICF.

ICFs Impact on Carbon Footprint

Before the invention of electricity, people built thick (adobe or ice) exterior walls to insulate and air-seal their homes, keeping them cool in the summer and warm in the winter. The extremely thick walls were the secret, so why not use that same logic today?

Architects and designers can build upon the simple, high thermal performance design using sustainable ICF mass walls, which provide maximum energy efficiency, prevent heat loss and eliminate thermal bridging. ICFs create exceptionally tight-building envelopes that minimize energy use.

In addition, ICF homes and buildings require less energy to cool and heat than traditional building methods, allowing ICF buildings to downsize their HVAC systems, which in turn, reduces the fossil fuels needed for heating and cooling, minimizing your carbon footprint.

Understanding Building Masses for ICF

The solid mass of ICF walls features several unique qualities, particularly when designing buildings that require excellent acoustics and year-round temperature control.

For Buildings Requiring Controlled Acoustics

When it comes to deadening sound, the thicker the wall, the better, which makes ICF construction the ideal solution for buildings requiring sound-dampening features. The solid mass and thickness of ICFs contain and reflect sound, lessening sound transfer through the walls, which is vital for controlling acoustics in condominiums, movie theaters and schools.

ICFs effectively dampen sound vibrations from unwanted outside noise, providing three times the sound resistance of a wood-framed wall, making ICF ideal for urban areas near busy streets or multi-residential builders where residents share walls. ICF walls have a sound transmission class (STC) of 50 or more, significantly greater than traditional wood stud walls that only have an STC rating of about 38.

For Energy-Efficient Buildings

ICFs contribute significantly to a structure’s thermal mass. ICF doubles the insulating value of the walls and creates a high thermal mass that controls temperature shifts within the building year-round, reducing energy use, saving money for the owner and occupants, and also helping the environment.

Simply put, thermal mass materials absorb and store heat energy, which is essential for controlling and maintaining indoor temperatures. For example, in hot regions, high thermal mass materials absorb and store cool air at night. The following day, as the temperature rises, the mass materials release the stored cool air into the interior, keeping the building cool.

ICF below- and above-grade walls stabilize the inside temperatures and lessen the need for heating and cooling equipment — all features that can help reduce the building’s carbon footprint.

If you build a below-grade ICF foundation for your garage, you will end up with a comfortable garage that you never need to heat: Your garage will never go below five or six degrees without mechanical equipment. If you leave the door open and the temperature drops a few degrees, it will immediately rise once the door is closed. ICFs and Mother Nature are doing the job that machinery normally does!

ICF Advantages

Contributes Towards Excellent Indoor Environmental Quality (IEQ)

ICFs create comfortable and healthy buildings, improving the well-being and productivity of the occupants:

- Using ICF as unit partitions or for external walls in multi-use buildings provides thermal mass and sound retention, creating acoustically comfortable spaces, lowering the resident’s stress, and contributing to peaceful work and living spaces.

- Because ICF walls do not contain organic material, they are resistant to mold and mildew growth — and the resulting degradation — as shown by third-party testing.

- Creates a healthy IEQ for the occupants of the building or home.

ICFs produce solid continuous monolithic concrete walls that manage moisture accumulation in the wall assembly, preventing the growth of structurally damaging mold and rot.

Wood that gets wet provides the nutrients and environment conducive to mold growth, unlike ICFs. Lower risk of moisture-related damage within the walls reduces the chances of mold and mildew infestation and the likelihood of negative health effects on people who are sensitive to mold. This is especially important in environments like hospitals, nursing homes and schools.

Construction Benefits

Flexible, modular and easy to install, ICF allows builders to quickly construct high-performing residential and commercial buildings, often with less labor. In addition, ICF provides several other building advantages:

- Various exterior finishes, like full bed masonry stone, perform great with ICF

- Allows direct application of drywall

- Permits easier routing of wiring and water pipes

- Does not require special engineering

- Installation can occur in severe weather conditions

- Eliminates stripping, form cleaning, insulation and furring steps

Disaster-Resistant Buildings

The strength of ICF provides several significant disaster-resistant components, minimizing or eliminating the costs of repairing or rebuilding after a storm:

Fire Resistant

ICFs provide passive fire protection, limiting the spread of flames during a fire.

Wind Resistant

ICF wall systems, with steel-reinforced concrete, contribute towards a continuous load path. The path holds the building together during severe wind, moving the force from the roof down to the ground. ICF walls also stop airborne debris from penetrating the exterior walls.

Earthquake Resistant

The sheer walls of ICF buildings stretch the entire height and all sides of the structure, making them resistant to seismic forces. As a result, during an earthquake, ICF walls effectively resist intense lateral (sideways) in-plane forces that push the top of the wall in one direction. At the same time, the bottom remains stationary or is pushed in the opposite direction (racking the wall).

ICF vs. Wood

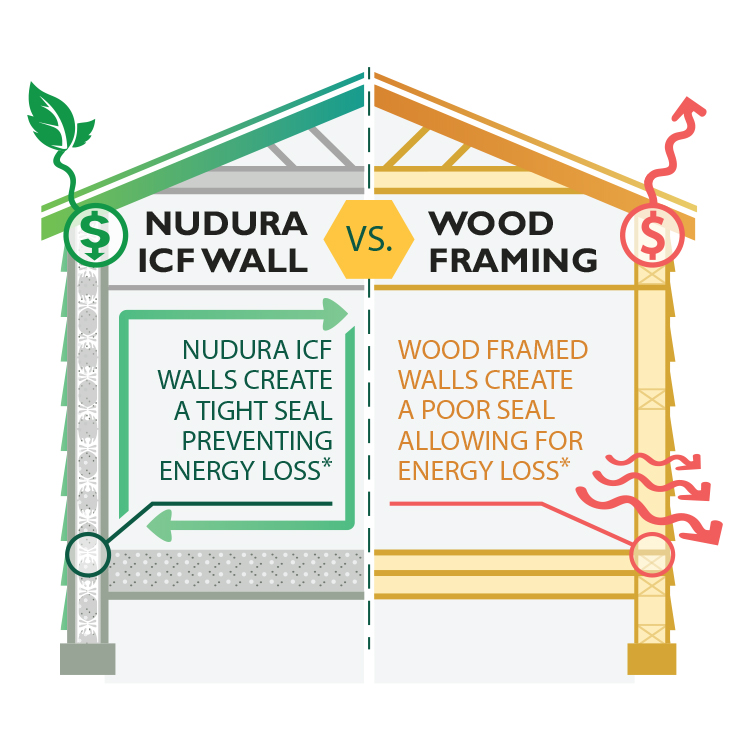

ICF wall systems provide many benefits over wood-frame walls, including enhanced energy efficiency and sound retention, disaster and pest resistance, and improved construction efficiency.

Energy Efficiency

ICFs create a solid, airtight mass with a range of R-value up to 24 and thermal mass properties of up to R-50 in certain geographical locations, to meet, if not exceed, the codes and standards of the ASHRAE 90.1 and 2021 IECC. ICF structures require 44 percent less energy to heat and 32 percent less energy to cool than similar wood-framed buildings.

Wind and Impact Resistance

ICF’s solid concrete core provides the strength and durability to stand up to 250 mph winds, along with debris flying at 100 mph, with greater durability and requiring less maintenance and repair over its lifetime than wood structures. Building a disaster-resistant wood-framed building costs 25–30 percent more than standard wood-frame construction.

Fire Resistance

ICFs can have a fire protection rating of up to four hours, which is four times that of a wood-framed structure.

Pest Resistance

Unlike pest-resistant ICFs, termites can severely damage the integrity of a wood-framed structure, costing thousands of dollars in repairs. In the U.S., termite damage and repairs amount to $5 billion.

Construction Efficiency

ICFs combine six building steps into one lightweight, simple-to-install form, expediting construction while also lowering building costs over wood-frame construction. This method reduces labor requirements and saves builders valuable time and money.

Insulated concrete forms are available in various shapes and thicknesses to accommodate all building designs and energy code requirements.

The Benefits of the Growing ICF Market

As architect, designer and builder awareness of ICF advantages grows, so will the market. In fact, experts predict a four percent compound annual growth rate (CAGR) for the ICF market between 2023 and 2028, driven by the need for energy-efficient and disaster-resistant buildings, along with the increasing demand for commercial construction and reduced building times.

ICFs help architects and contractors create disaster-resistant, sound-dampening, healthy and sustainable structures. They save money by accelerating project delivery time, reducing labor needs and lessening energy costs.

If you need assistance with your first ICF build or have a unique design challenge, Nudura is here to help.

|

About Scott CarpenterScott has over 35 years in the construction industry with over 15 years of in-field construction site work and 20 years in the ICF industry in various capacities including technical, sales, and training support. He has a vast understanding of what contractors, designers, engineers and owners needs are, which helps in project-specific problem solving. |

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.