Concrete wall forms are temporary or permanent molds for holding poured concrete to erect load-bearing walls. Concrete formwork can be made of different materials including wood and extruded polystyrene (EPS) foam insulation. With wood, the form is typically removed after the concrete has cured. Stay-in-place concrete forms manufactured with insulation are known as Insulated Concrete Forms or ICFs. ICFs create monolithic walls of concrete that are steel-reinforced and protected on each side by a layer of continuous insulation. Some ICF blocks even have one layer of insulation and a removable layer of wood on the opposite side for an exposed concrete look.

Structural concrete framing, on the other hand, is comprised of interconnecting precast or cast-in-place concrete columns and beams that support the floors, walls and roof. The floors and walls may also be constructed of precast or cast-in-place concrete. A concrete frame, also known as a concrete skeleton, can carry strong loads, but it does not typically include the solid concrete wall that is sought after with concrete wall forms and ICF systems.

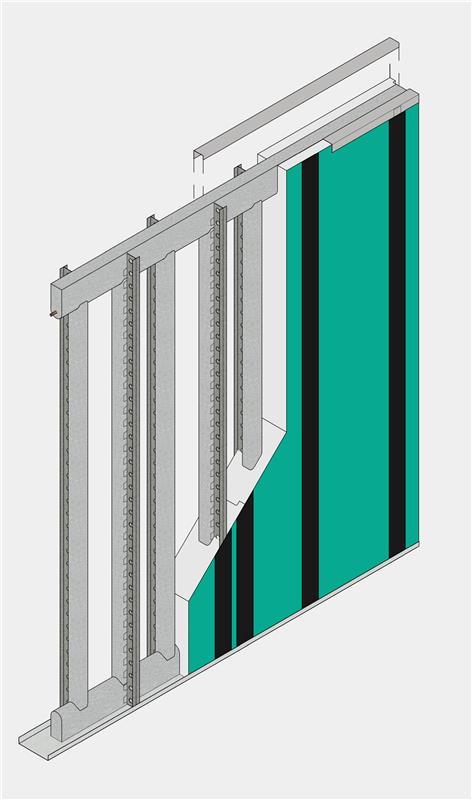

Insulated concrete panels, or ICPs, like HercuWall™, combine the concept of concrete framing with built-in insulation for a prefabricated solution that is delivered to the jobsite ready to install. The HercuWall system has 3 in. by 3 in. concrete studs that extend the full height of the wall with EPS insulation in between and a weather-resistant exterior film.

Insulated Concrete Form systems simplify the process of building reinforced concrete walls while ensuring structural integrity and thermal efficiency. Completed ICF walls are designed to withstand heavy loads and high-pressure forces, including natural disasters like tornadoes and hurricanes. They also offer significant insulation benefits, which help reduce a building’s energy consumption. By improving energy efficiency, these systems are an excellent choice for achieving sustainable construction goals, including net-zero energy and LEED certification.

Another advantage of concrete wall forms is their design versatility. Some manufacturers offer corner forms, radius blocks and custom geometries for infinite building configurations. Countless exterior cladding options can be installed over an ICF wall to accommodate any architectural aesthetic. With this flexibility, concrete forms are used across residential and commercial buildings where high strength and sustainability are required.

Known for its stability, concrete framing provides a more durable alternative to traditional wood or steel framing. The thermal mass of concrete minimizes heat transfer better than wood and steel, but additional interior and/or exterior insulation is required for the walls of these structures.

Various façade materials can be used with concrete framing for added customization. Concrete framing is used predominantly in commercial construction projects like parking garages and hotels.

For structural walls at a lower price point, insulated concrete panels offer the best of both worlds. They use 1/3 the concrete of precast concrete walls and ICF systems and provide R31 insulation for energy efficiency. While each panel of HercuWall can stand up to 14 ft tall, they can be stacked for multi-story buildings. Insulated concrete panels are limited to above-grade applications but can be combined with other below-grade construction methods, like ICF basements or foundations. For the building’s exterior, these structural wall panels are an approved substrate for the most common cladding types, including stucco and horizontal siding.

Concrete buildings have greater strength and energy efficiency compared to wood-frame and steel-frame structures, but there are many different ways to achieve this. Therefore, it is helpful to understand the nuances between concrete forms, concrete framing and insulated concrete panels to choose the approach that aligns best with your project’s needs.