ICF 101

Welcome to ICF 101, your crash course on all things Insulated Concrete Forms. Explore how ICF construction aids designers, builders and homeowners with basements, foundations and structural walls all the way to the roof.

Welcome to ICF 101, your crash course on all things Insulated Concrete Forms. Explore how ICF construction aids designers, builders and homeowners with basements, foundations and structural walls all the way to the roof.

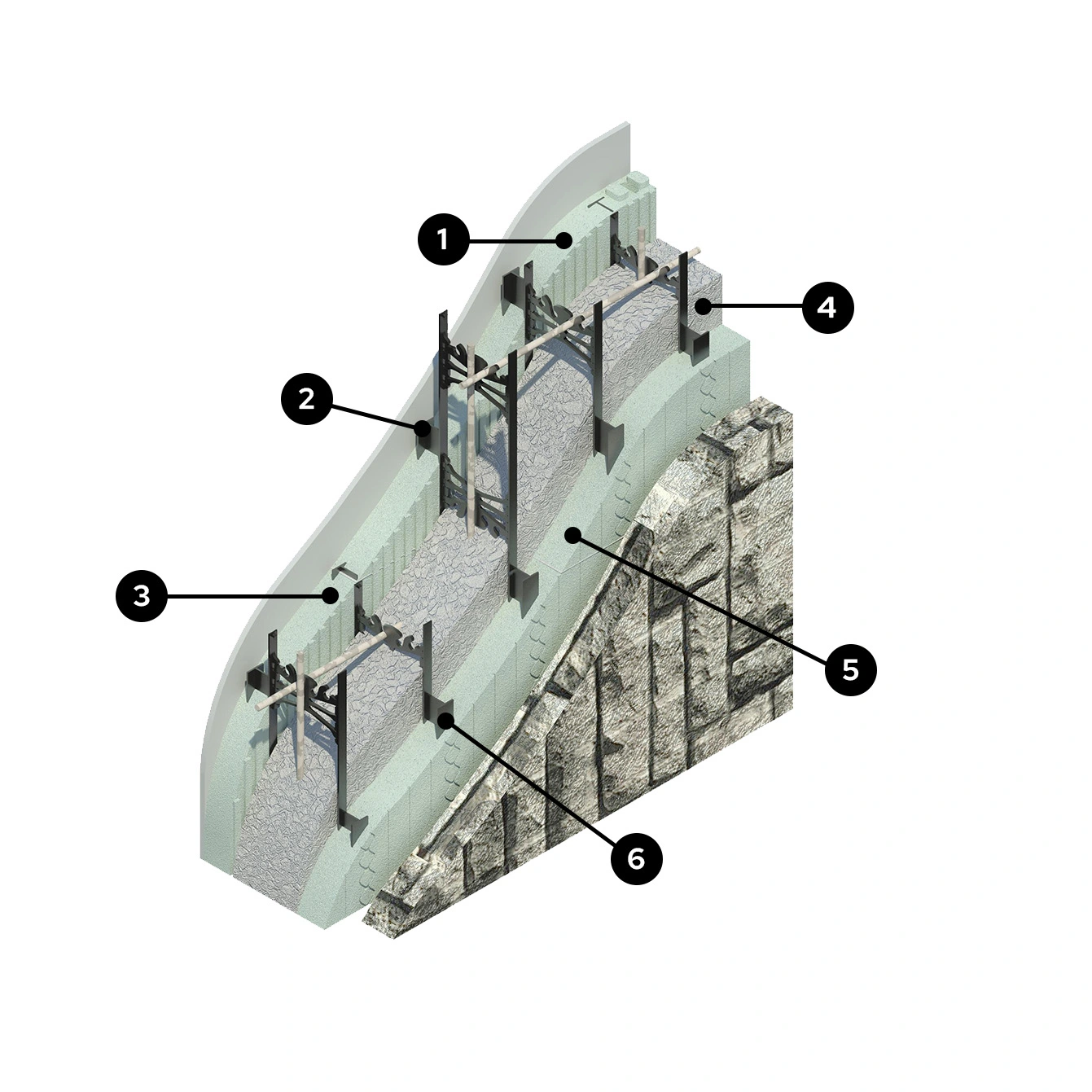

Scroll through the different elements that make up an Insulated Concrete Form assembly.

Here are the simple steps to build with ICFs. For a more detailed and technical walkthrough, join our in-person and online ICF construction training courses.

Nudura® Insulated Concrete Forms condense six building elements into one to streamline building construction. Take a look at our 6-in-1 system!

Why build with ICFs? Check out the benefits of Insulated Concrete Forms and how they enhance both the building process and the quality of the finished structure.

ICFs reduce a structure’s energy consumption by minimizing air leaks, thermal bridging and heat transfer through the walls.

Insulated Concrete Forms come in many shapes and sizes for design flexibility. They can also accommodate virtually any exterior finish, including masonry, siding, stucco, EIFS and exterior panels.

ICFs are lightweight, easy to stack and can be installed year-round. By speeding up wall construction, subsequent trades can proceed sooner, and tenants can occupy the building sooner.

ICFs boost building comfort by providing soundproofing, improving the indoor air quality, and promoting consistent interior temperatures.

Even during extreme weather conditions, Nudura ICF wall assemblies can endure winds of up to 250 mph (402 kph) and prevent wind-blown debris from breaching the building exterior.

ICFs provide passive fire protection, limiting the spread of flames during a fire. Nudura ICF walls have a fire-rating of 4+ hours, compared to wood-frame walls, which have a 45-minute rating.

ICFs contribute to the sustainable design of buildings through their increased energy efficiency, longevity, reduced need for lumber and lack of material waste.

See how ICFs benefit everyone throughout the construction process.

Nudura offers a variety of online resources to support you in your ICF journey, regardless of your role in building design and construction.

Check out our blog, YouTube channel and training opportunities for the latest ICF educational content!

For more technical data, visit our product pages or see these resources:

To learn more about Insulated Concrete Forms, dive into these product features:

Net-Zero

Disaster Resiliency

ICF vs Other Construction Methods