As you’re planning your Insulated Concrete Form (ICF) build, selecting the right window buck system affects everything from budget to installation complexity to your structure’s thermal performance. Window bucks create finished punched openings and serve as the foundation for transitioning the glazing system to the wall assembly, so they’re critical to get right. With numerous bucking technologies on the market for ICF walls, it’s important to know how each can impact your concrete building during and after construction.

This blog post will help you understand the differences between PVC, EPS, steel and wood buck options so you can make the material selection that best matches your ICF project requirements.

Traditional Wood Bucking

Traditional Wood BuckingStandard wood window bucks are a common and affordable route, but can require a lot of field measuring and cutting to get the right fit for your wall openings. With the pressure exerted during an ICF concrete pour, there are some concerns about the strength of these bucking systems. This concern extends post-construction, as the stay-in-place wood can be susceptible to warping, twisting, decay and termite damage.

In addition, untreated lumber cannot be in direct contact with concrete. For the attachment of the lumber to the concrete, usually fasteners are installed on the backside (concrete side) of the buck which grab into the concrete. However, this critical connection is only at these fastener points and is not continuous around the entire buck.

This can be problematic with the common challenge that most lumber is not entirely straight, which could result in air leakage around the openings. It is also increasingly difficult to get lumber wide enough in one piece to accommodate wider width walls, forcing installers to use multiple pieces leading to more field work and thermal breaks.

PVC and Expanded Polystyrene (EPS) buck systems offer a more affordable starting point for window framing in ICF construction. They are best suited for residential applications and have the lowest material cost.

However, there are some drawbacks to selecting the budget-friendly option. Both PVC and EPS buck systems require wood shoring and bracing during concrete pouring and placement to prevent bowing or deflection. The additional labor can offset some of the upfront savings. These systems also have shear and pullout resistance limitations, which restrict the attached glazing system and finish material options . There are also limited fastening options with this route, so while the bucks might have fastening strips in them, they may not be in the exact spot needed for the attachments.

Commercial-Grade Steel Bucking

Commercial-Grade Steel BuckingSteel buck systems are best suited for commercial buildings, including high-wind-load structures, FEMA/ICC 500 storm shelters and military projects, where structural performance cannot be compromised.

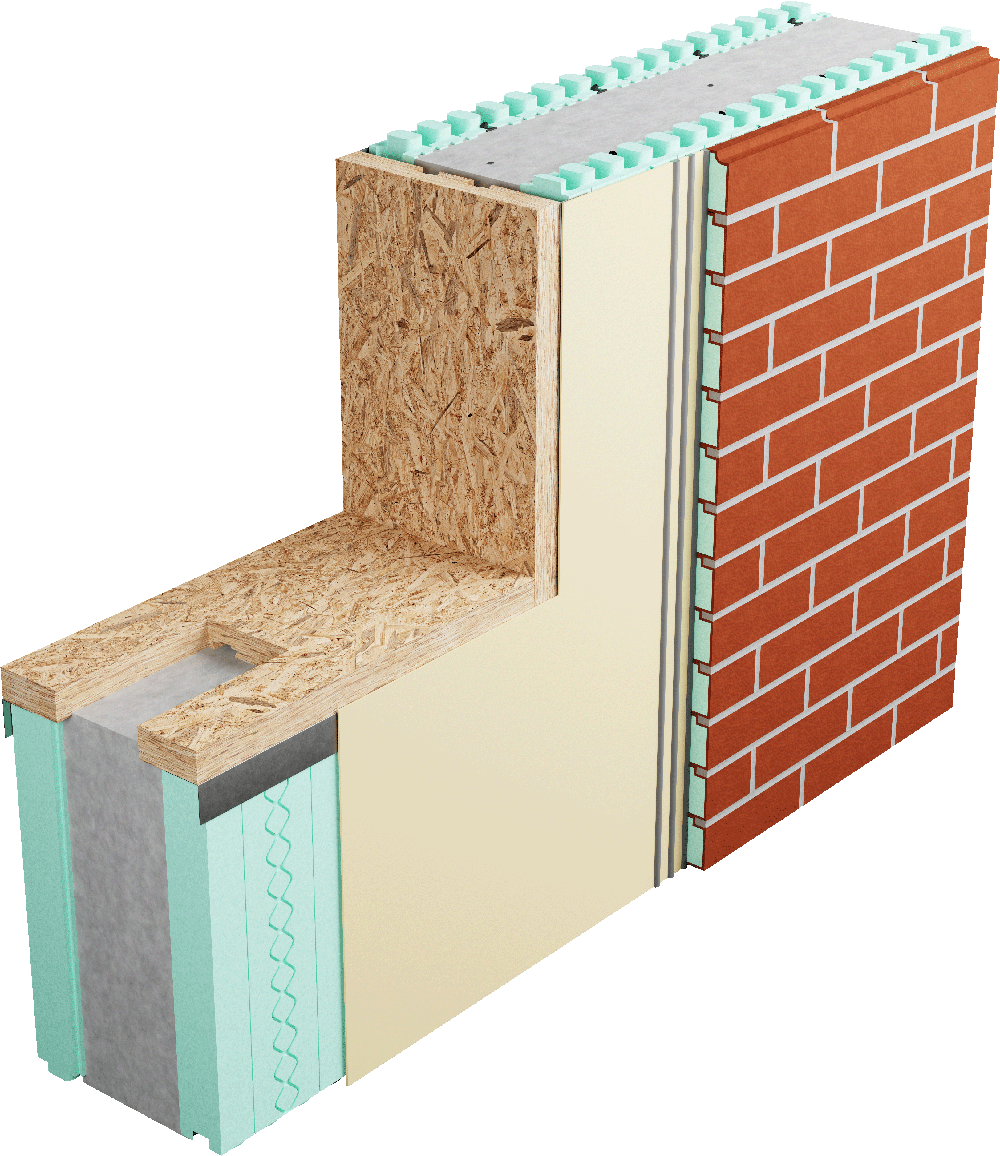

Modern steel bucks feature two-part designs that arrive pre-primed and ready for painting. The thermal break prevents heat transfer through the frame, maintaining a high-insulation performance in the wall. Steel systems accommodate various ICF wall thicknesses and can be manufactured in custom shapes, including Gothic arches and polygonal openings.

They can also include exterior extensions that close off wall cavities when brick veneer is used. The extension provides full backup support for the glazing system attachment, and the interior design accommodates 5/8 in . (15.87 mm) gypsum board to reduce the finishing time for jambs, sills and heads around openings.

A versatile bucking material for both commercial and residential construction, engineered wood systems using Laminated Strand Lumber (LSL), like Prebuck®, are the ideal solution for ICF walls, since they have superior strength compared to conventional wood systems and are made for direct contact with concrete. LSL bucking can be incorporated with other types of wall assemblies as well, so you can use them across your projects.

Prebuck also has the option to be delivered to the jobsite with a pre-cut length to minimize field work. Similarly, the product comes rip cut to the required wall widths as a single piece, so you don’t have to combine multiple pieces together for wider width walls.

Prebuck also has the option to be delivered to the jobsite with a pre-cut length to minimize field work. Similarly, the product comes rip cut to the required wall widths as a single piece, so you don’t have to combine multiple pieces together for wider width walls.

The engineered wood is termite-resistant and remains in place after concrete placement without the warping issues common with pressure-treated lumber. Prebuck window bucking requires less shoring and bracing compared to EPS and PVS systems and the 1.5 in. (38 mm) thickness provides excellent attachment points for interior and exterior finish systems.

LSL systems also contribute to the thermal efficiency of the structure with an R-value of R-1.25 per inch. For a 4 in. (102 mm) wide frame, that is an R-5 insulation value, which often exceeds that of the window glass. The thermal performance of Prebuck is why this technology is often chosen for net-zero projects and buildings seeking maximum energy efficiency.

With Insulated Concrete Form walls, Prebuck bucking systems are easily installed as the ICF blocks are stacked for a faster construction process. Derek Bayer of Bayer Crete, Inc. used Nudura ICFs and Prebuck during the construction of the UPMC Medical Center in Hermitage, Pennsylvania and described that, “There’s 27-30 windows, 7 or 8 doors, and two big vestibule doors, and we had it all put together in less than a day.”

The right bucking system sets the basis for a seamless window installation and the long-term structural integrity of the building. For Insulated Concrete Form construction, there are additional factors to consider when choosing the right window bucking material, beyond just thermal goals and budget. Prebuck has this ease of installation, versatility and durability to make it the ideal solution for bucking with ICF walls.